toppage

Biocellulose is a natural fiber synthesized by bacteria.

It is thin, tough, has water retention, and perfectly sticks to the skin.

It delivers moisturizing ingredients deep into the keratin and moisturizes dry skin.

Biocellulose is a natural fiber synthesized by bacteria.

It is thin, tough, has water retention, and perfectly sticks to the skin.

It delivers moisturizing ingredients deep into the keratin and moisturizes dry skin.

Features of Biocellulose

Animal Free

Biocellulose, which is mainly made from coconut water and does not contain any animal-derived ingredients.It is all plant-derived, so there is no need for animal experiments.

Vegan material

Biocellulose comes from 99.9% natural materials (Coconut water, water, bacteria). Because it is a material that will adhere to the skin, we pay particular attention to the naturalness and value the creation of products that can be used with peace of mind.

Sustainable

Biocellulose, which makes one mask from one coconut, is an environmentally friendly biodegradable fiber. It is a sustainable fiber that decomposes into carbon dioxide and water through enzymes secreted by microorganisms and returns to nature.

Safety and security

Because biocellulose is made from a plant-derived raw material, it has very high bio-fusion properties and is a safe material that easily adapts to the skin.

Nanofibers

Because it forms fibers in three dimensions at about one thousandth of a hair, it has a silky smoothness,expansion and contraction power and is firmly attached to deliver moisture to the skin.

Highly moisturizing

The ultrafine fibers are densely engineered to form fibers in three dimensions. Even if left on the skin for a long period of time it will continue to deliver moisture to the outer layer of the skin, never leaving the skin thirsty.

Animal Free

Biocellulose, which is mainly made from coconut water and does not contain any animal-derived ingredients.It is all plant-derived, so there is no need for animal experiments.

Vegan material

Biocellulose comes from 99.9% natural materials (Coconut water, water, bacteria). Because it is a material that will adhere to the skin, we pay particular attention to the naturalness and value the creation of products that can be used with peace of mind.

Sustainable

Biocellulose, which makes one mask from one coconut, is an environmentally friendly biodegradable fiber. It is a sustainable fiber that decomposes into carbon dioxide and water through enzymes secreted by microorganisms and returns to nature.

Safety and security

Because biocellulose is made from a plant-derived raw material, it has very high bio-fusion properties and is a safe material that easily adapts to the skin.

Nanofibers

Because it forms fibers in three dimensions at about one thousandth of a hair, it has a silky smoothness,expansion and contraction power and is firmly attached to deliver moisture to the skin.

Highly moisturizing

The ultrafine fibers are densely engineered to form fibers in three dimensions. Even if left on the skin for a long period of time it will continue to deliver moisture to the outer layer of the skin, never leaving the skin thirsty.

Amazing water retention and adhesion

Biocellulose is a highly functional natural cellulose produced by cultured fermentation with acetic acid bacteria using bacterial coconut water as a medium. “Biocellulose” The gel-like high-density sheet made of nano-level ultra-fine fibers has excellent water retention and adhesion, and enables efficient penetration of serums into the skin.

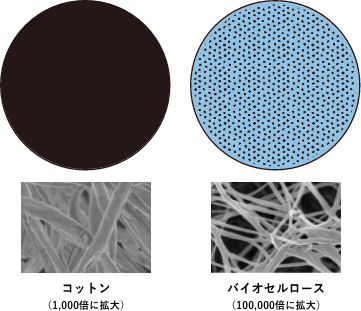

Biocellulose is three hundred times thinner than cotton and can absorb about seventy times more moisture.

Biocellulose fibers are 50-100 nm. This is one three hundredth the thickness of regular cotton. Fine fibers, also called “nanocellulose”, are not only unidirectional, but also have high strength by weaving three-dimensionally and are rich in flexibility and elasticity. It has excellent water retention and is an amazing material for cosmetics.

Two times the water retention of cotton and two times the strength.

One-stop from material procurement to manufacturing

Our biocellulose is produced in our own factory in Vietnam. Coconuts are sourced from locally affiliated farms. After the fermentation process, it is processed into sheet materials at our own factory that has cleared cosmetics GMP (ISO 22716). The processed sheet material is transported to Japan and processed into the final product at the Yamanashi Plant.

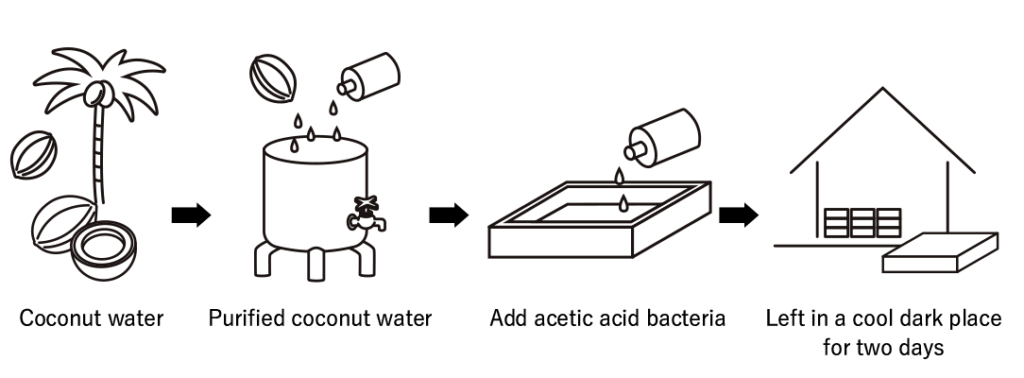

Medium production, fermentation, cellulose formation

Add acetic acid bacteria to fresh coconut water and purified water. Coconut water medium with added bacteria is placed in the fermentation chamber for 7-10 days. At the end of fermentation the gel-like cellulose colloids are formed.

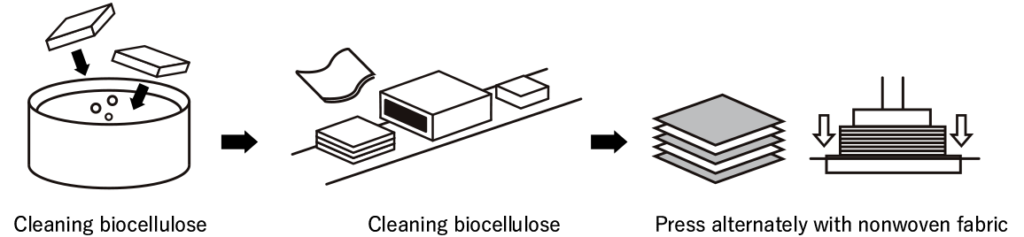

Cleaning, lamination, forming into mask

The raw cellulose material produced after fermentation is washed and dehydrated repeatedly to remove impurities. After slicing the refined raw fabric, it is laminated with the layer material in layers, pressed, dehydrated and then formed into the mask shape.

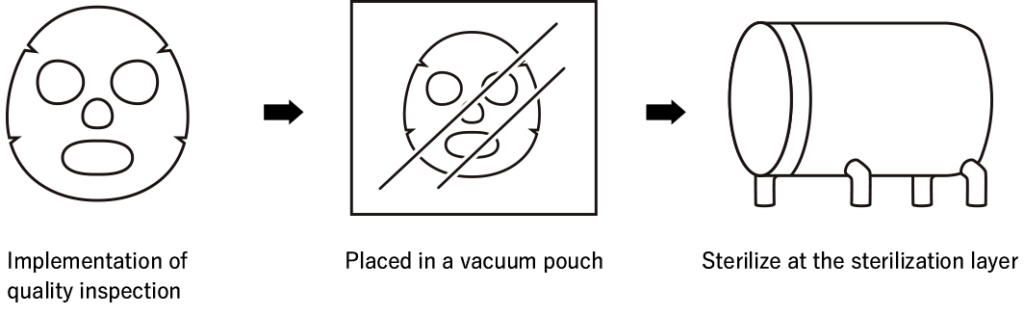

Finished packaging

Each die-cut biocellulose mask goes through a quality inspection process before being placed into a vacuum pouch. Finally, the sterilization process is performed and the preparation for shipping is completed.

Transportation of sheet materials to Yamanashi Plant

At the Yamanashi Plant, we process it into Japan-quality biocellulose cosmetics.

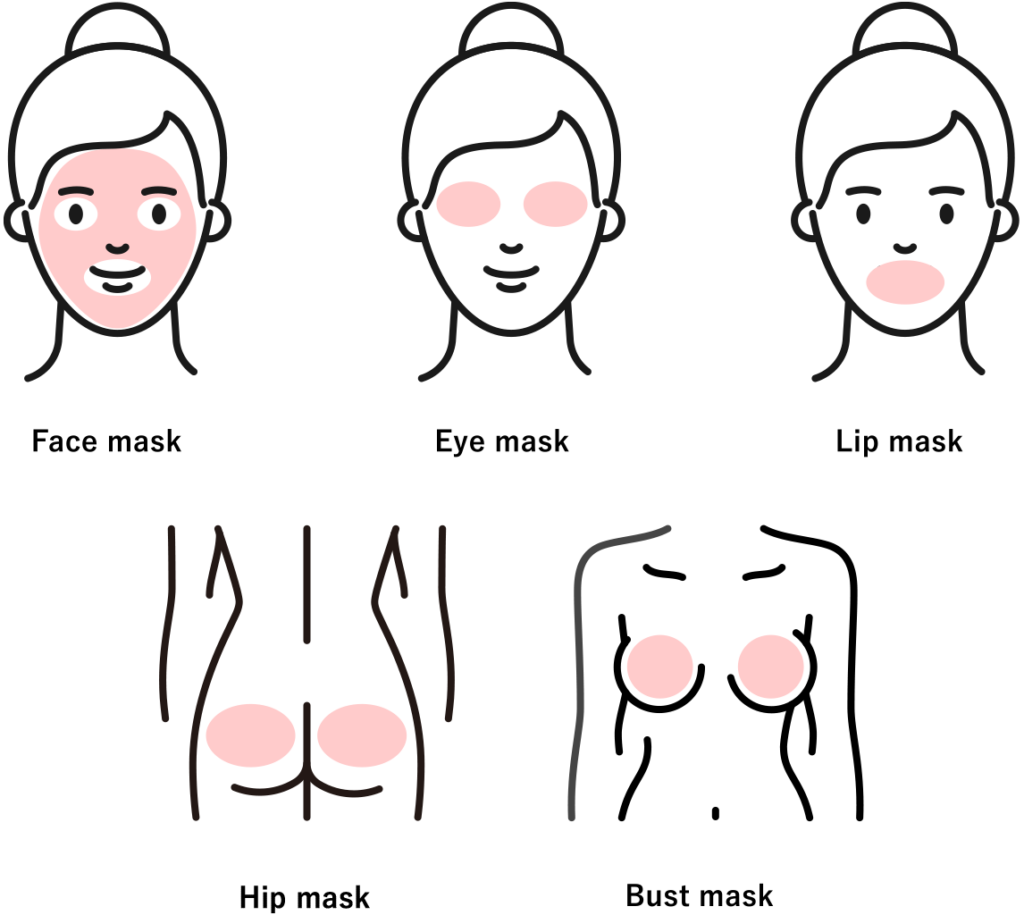

What ever ideas you have

Why not make cosmetics with biocellulose?

Cosmetics made from biocellulose

The delivery time of OEM products is usually about two and half to three months after formulation and design decision.

Please do not hesitate to contact our sales staff. They will try to give the most detailed delivery date as possible.

Adjust the quantity production schedule according to the timing of the material delivery date.We prepare for filling ahead of time so as to complete it in the shortest possible time. The automatic filling and packaging machine has a production capacity 3000-4000 pieces per hour. On average, it is possible to produce about 30,000 pieces of biocellulose per day.

For inquiries by phone, click here

Tel.03-5337-0625

Please contact us by phone from 10: 00 to 17: 00 on weekdays (excluding weekends and holidays).We accept emails 24 hours a day (open all year round), but if it is a company holiday, we will respond after the next business day.